DUPLEX ROLLER HEAD UNIT

Overview

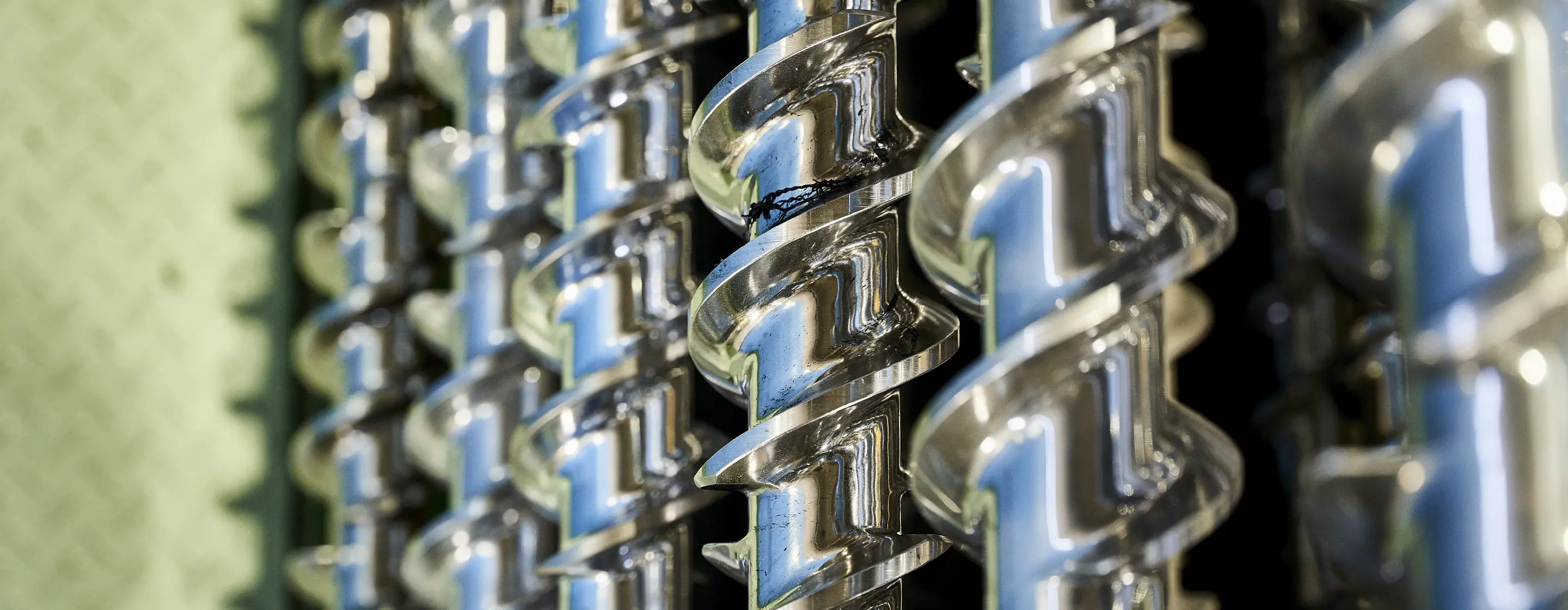

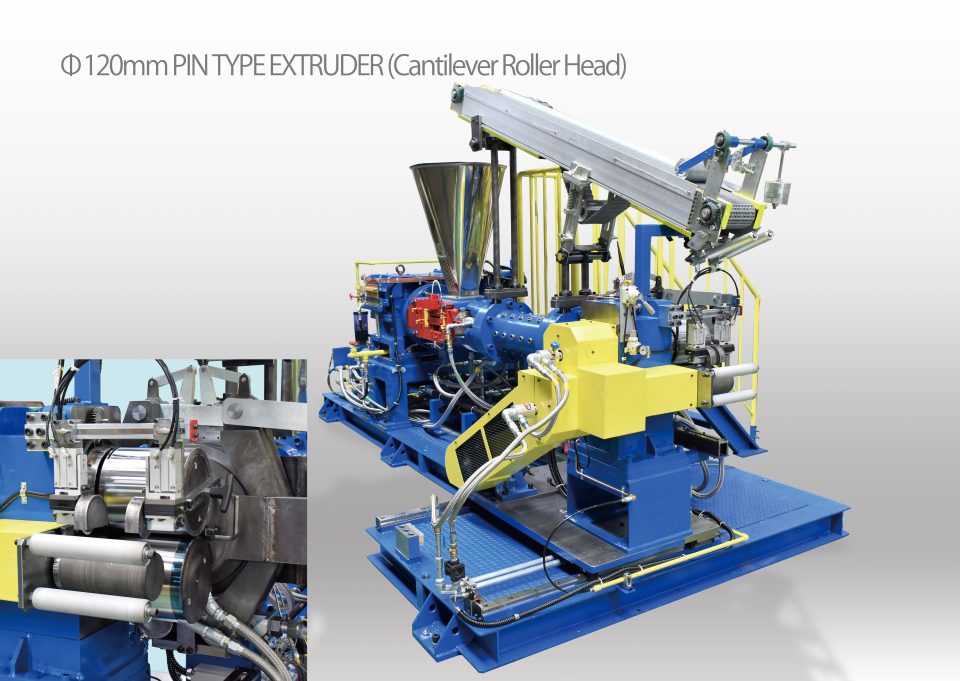

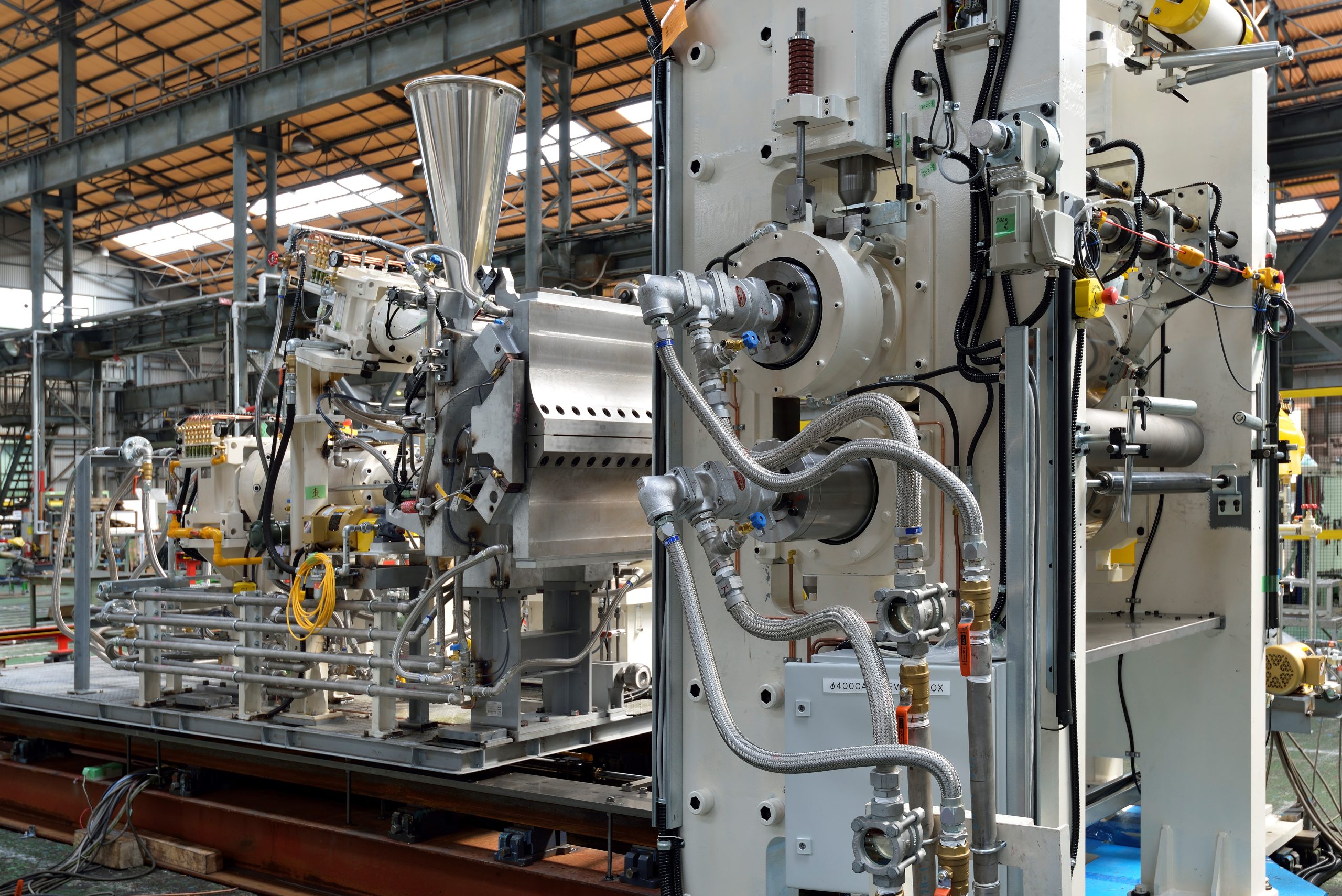

The roller head unit consists of a single or duplex extruder, a die head, and a vertical two-ball calender with head clamping devices. The broad width head and calender form the rubber compound into a sheet of uniform thickness, which can be varied from 0.5 mm -20 mm or greater in thickness. Nakata roller head units provide significant benefits over conventional calender systems in the production of inner liners, rubber sheets, V-belts, and elastic components.

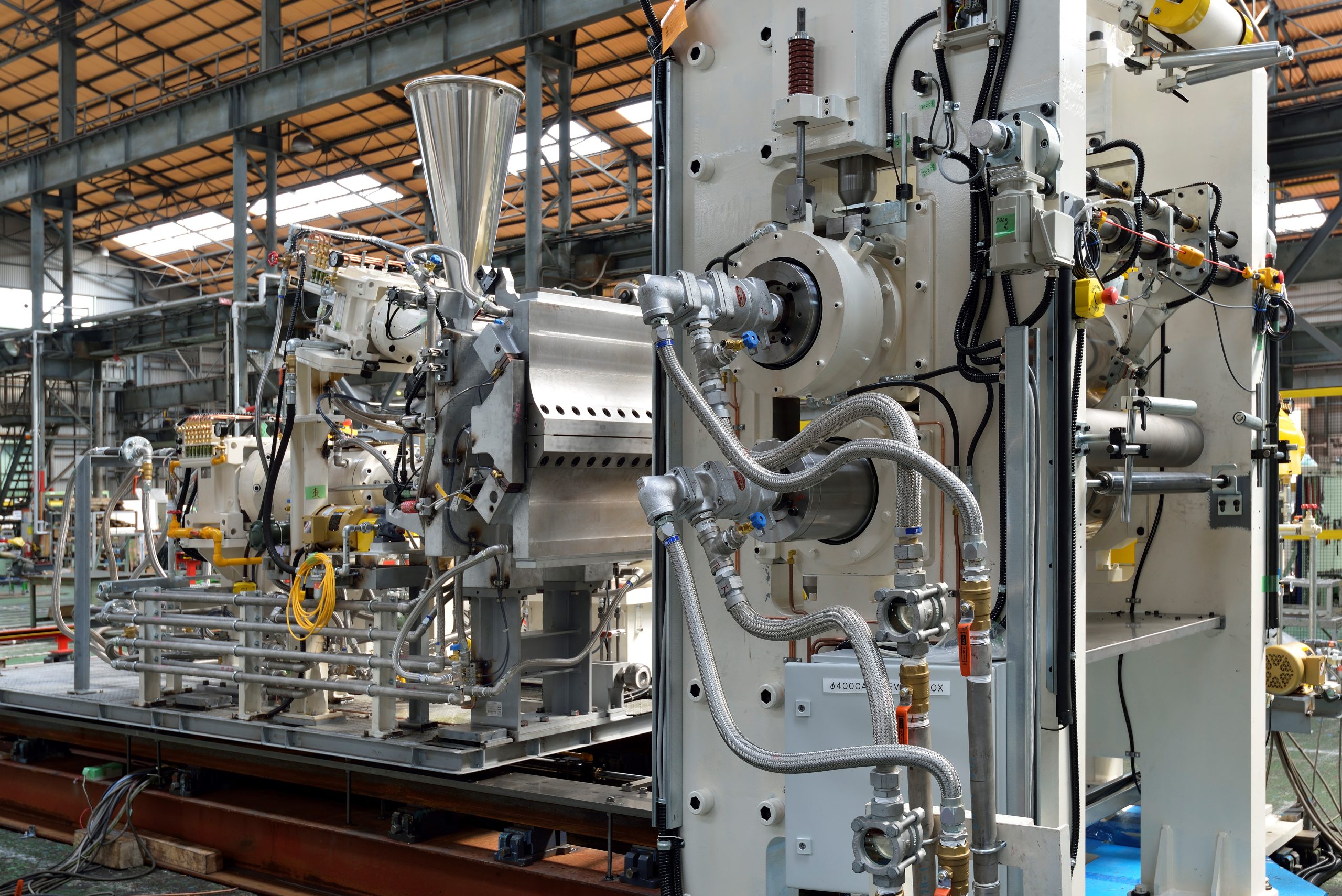

DUPLEX ROLLER HEAD UNIT

The duplex roller head unit consists of two extruders, a die head, and vertical two roll calender. The rubber is evenly distributed in the die head over its entire width, and is then fed into the calender nip. A feedback system of control varies the RPM of the extruder screw or calender speed so that high quality rubber sheet (up to 2300 mm wide) can be produced in thickness from 0.5 mm to 20 mm or greater.

Duplex roller head system

Various configurations of duplex extrusion sheets

Specification

Major Specifications of Extruder and Roller Head System

| Sheet head aperture | Calender roll | Product sheets | ||||

| Motor capacity kw | Width (mm) | Height (mm) | Roll diameter | Surface length | Width (mm) | Thickness (mm) |

| 200 | 1850 | 30 | <600> | <2000> | 1450 | 1.5〜9 |

| 450 | 2300 | 28 | 700 | 2500 | 2200 | 1〜15 |

| 300 | 1300 | 28 | 500 | 1500 | 1200 | 0.5〜4 |

| 200 | 1050 | 28 | 400 | 1300 | 270〜 | 0.5〜5 |

| 110 | 700 | 10 | 500 | 1500 | 1250 | 0.1〜1.0 |

| 45 | 600 | 22 | 310 | 900 | 500 | 1.5〜5 |

| 30 | 550 | 8 | 400 | 700 | 550 | 0.2〜2.0 |

| 18.5 | 185 | 5 | 200 | 250 | 100 | 0.5 |

| 7.5 | 95 | 3 | 120 | 150 | 100 | 0.3〜2 |

| 4.4 | 30 | 3 | 80 | 48 | 40 | 0.5 |

Related products

-

Roller head unit that has advantageous characteris……

-

AUTOMATIC SLEEVE EXCHANGE ROLLER HEAD UNIT

Roller head unit that has advantageous characteris……

-

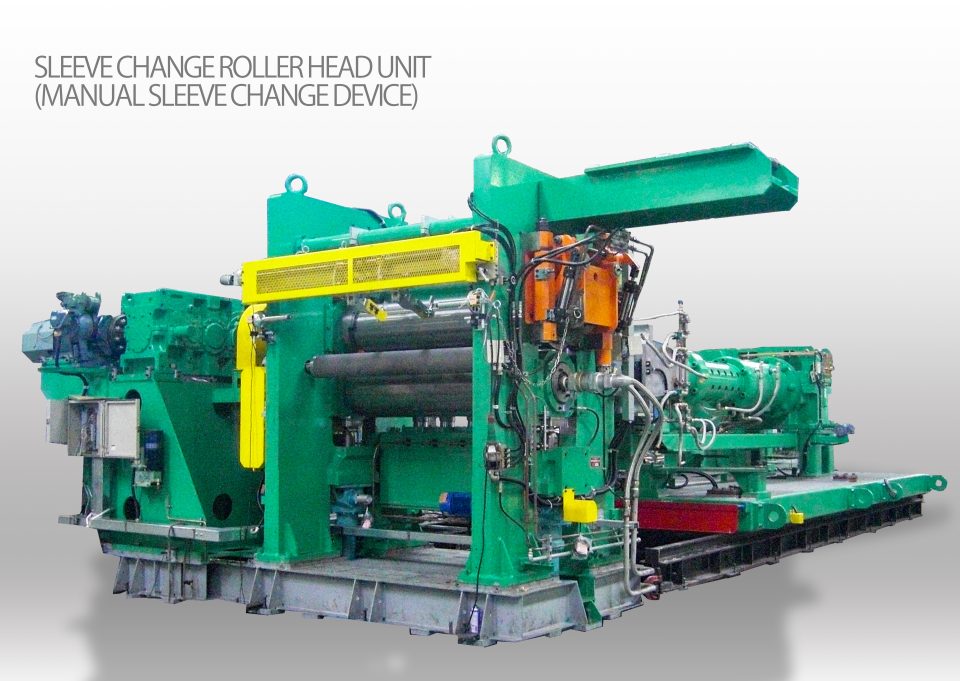

MANUAL SLEEVE EXCHANGE ROLLER HEAD UNIT

Roller head unit that has advantageous characteris……

-

Roller head unit that has advantageous characteris……